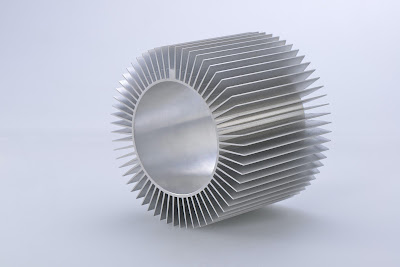

Aluminum extrusion is a process where aluminum is forced through a die of the desired cross-sectional shape. The aluminum extrusion process begins with a billet, a rectangular piece of aluminum placed in an oven to be heated to approximately 700 degrees Fahrenheit. Once the billet is heated, it is placed on a loading table and fed into the extruder.

The extruder contains a ram that applies pressure to the billet, forcing it through the die. As the aluminum is forced through the die, it takes on the shape of the cross-section of the die. After the aluminum has been extruded, it undergoes a cooling process before being cut to length. Aluminum extrusion can be used to create a variety of shapes and products, such as pipes, tubing, and window frames.

Aluminum extrusion has many advantages over other manufacturing processes, such as casting and stamping. Aluminum extrusions are stronger than castings and have a higher degree of precision. In addition, aluminum extrusions can be produced in various shapes and sizes. Aluminum sheet panels for cars or aluminum siding for home’s walls and roofs.

Aluminum extrusions are also lightweight yet strong, making them ideal for aircraft and automobiles. Extruded aluminum also has good corrosion resistance and can quickly form complex shapes. These properties make aluminum extrusion an ideal choice for various applications.

Aluminum extrusion is a process by which aluminum is shaped into specific products. The aluminum is placed in a die, and a hydraulic press is used to push the aluminum through the die. This process can be used to create a variety of shapes and products, including pipes, tubing, rods, and more.

Aluminum extrusion has several advantages over other methods of shaping aluminum. For one, it is much faster than other methods. Additionally, it can create products with exact dimensions. The extrusion also allows for much customization, as different dies can create different shapes.

The Benefits of Aluminum Extrusion

There are many benefits to using aluminum extrusion. For one, it is a speedy process. In most cases, the entire process can be completed in just a matter of minutes. Additionally, extrusion allows for exact dimensional control. This means that products made via extrusion will always meet your specifications.

The extrusion also offers a great deal of customization potential. You can create products in nearly any shape or size using different dies. This flexibility makes extrusion ideal for applications requiring precise dimensions, but standard shapes will not suffice.

Finally, aluminum extrusion is relatively inexpensive compared to other methods of shaping aluminum. This makes it an ideal choice for applications where cost is a significant concern.

Conclusion:

Aluminum extrusion is a versatile manufacturing process that offers many advantages over other methods, such as casting and stamping. Aluminum extrusions are solid yet lightweight, precise, and resistant to corrosion. In addition, they can be easily formed into complex shapes. These properties make aluminum extrusion an ideal choice for various applications ranging from plumbing to aircraft construction.

Who are we?

We are an aluminum enthusiast, a surplus aluminum supplier in Canada and the USA.

Furthermore, we have extensive blogs about aluminum metals and their benefits. Some examples are:

Are aluminum canoes good?

Does aluminum help with soundproofing?

How To Make Your Aluminum Product Look Like New Again?

Are aluminum bats better than wood?

What Is The Difference Between Aluminum And Anodized Aluminum?

Additionally, if you ask your device to find “aluminum coil “ near me

or

Find “aluminum sheets “ near me in Toronto; you will find us on Google Maps. Hooray!

Additionally, if you ask your device to find “Aluminum Foil “ near me in Toronto,

Or

Find “Aluminum Wire “ near me in Toronto; you will find us on Google Maps. Hooray!

Call us at 905-764-2245 if you ever need premium aluminum metals in Toronto, Canada and the USA.

No comments:

Post a Comment